It’s been a few weeks since this little frame arrived, so after the small change of subject and posts about Dave Yates and his brilliant frame building course, it is back to the SBDU and Ilkeston built bikes. I’ve had a chance today to get the tools out so I can try and figure out what this bike is because so far I haven’t got a clue what I have. Second hand bikes don’t normally come with documentation, receipts or build sheets; they rarely come from the original owner who would have first hand knowledge of what they were passing on. Second hand bikes are very much a mystery! In order to categorise what you have, you need to research, measure and compare to known information. At the moment, it is a 531c tubed bike made by SBDU in approximately 1982. I only think it is 531c as it has a sticker saying so, but that could have been fitted by anyone.

It only takes a few minutes and a few simple tools to get ready to measure a frame. A set of wheels – mine are Mavic sprints with Clement tubs; those together with a standard road headset get the stance right on the workbench. I then have a few metal rules, a set of digital calipers and an app on my iPhone to digitally measure angles. You can easily find a frame diagram on the internet, or just draw your own. I also have some documents from the TI-Raleigh Yahoo group that lists the stock dimensions of Road and Time Trial Special Frame sets.

Modern bikes show a clear difference between a road ‘racing’ bike and a time trial bike, you can see it at a glance, but in the era of the 70s and 80s, you had to look closely to see them. Time Trial frames of this period differed to road frames in a few different ways. Two main differences are…

Weight – you can’t see it but you can feel it. Most time trial bikes were built from a lighter tube. The classic time trial special model built by SBDU was made from Reynolds 753. If you didn’t want the cost or harshness of 753, you could go to something like Reynolds 531 Special Lightweight (SL) which was a similar weight tube but without the ‘heat treating’ of it’s more exotic counterpart. Weight was also kept down with the use of shorter, tighter geometry and choice of components. A shorter frame means shorter tubes which means less weight. Time trial bikes would often have shorter top tubes and shorter chain stays. But even all of this meant that frames still looked very similar at first look.

Geometry – Lots of books are written on frame geometry and lots of people have lots of ideas, right or wrong, about how things should be. Geometry should make the bike fit the person and make the frame fit the purpose of the bike. It is sometimes a balancing act as changing one aspect of frame geometry can have a knock on effect on others. Each independent frame builder may have had a formula for building their own time trial bikes. SBDU had a stock time trial geometry that centered around vertical rear dropouts, shorter top tubes and chain stays, higher bottom bracket shells, steeper seat angles and a shorter fork rake. Although vertical rear dropouts are now the ‘norm’, they were very much not the ‘norm’ in this period. Of all these features, the vertical dropouts are the easiest to spot and this is what I spotted first on this frame.

Chain stays with horizontal drop outs need to be longer to allow the rear wheel to move forward and clear the seat tube in order to drop out of the frame. If the stay was too short or the clearance wasn’t there or if the tyre was too big then the tyre would sometimes need to be deflated to remove the wheel from the frame.

With a vertical drop out, the wheel doesn’t need to slide forward so the clearance isn’t needed and the chain stay can be shorter. An advantage of the shorter chain stay is a stiffer rear triangle which lends itself to more effective use of power and less power loss. There are lots of resources on the internet from people much more knowledgeable than me so I’ll leave geometry there; but one of the blogs I like to read to explain geometry is Dave Moulton’s blog.

Because this frame is very light and has vertical drop outs, it has the appearance and feel of a time trial frame so I was keen to confirm it by measuring. Fortunately, there is information available about all of SBDU’s geometry that I can use to check to see if this is a Time Trial Special. This is a document kindly provided by Mike Mullett, ex workshop manager at SBDU and also accomplished frame builder in his own name.

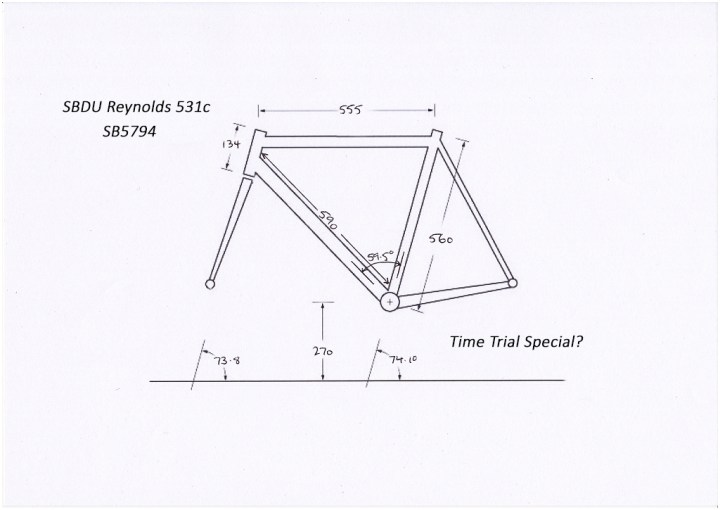

My frame is a 56cm so reading across the table above, I’m hopefully going to see the key measurements of a 555 mm top tube, 134 mm head tube, a BB height of 270 mm and angles of 74.1/73.8

First thing to do is zero my digital angle app to ‘0’ degrees on the top tube – that will set it to be able to accurately measure the seat and head tube angles as they are both measured against the horizontal. It is also difficult to know exactly where the centre of the BB shell is as it is just an empty circle. To get around this, measure the outside circumference of the BB shell and divide it by 2 to get the radius. In my case, the diameter is 40 mm so the radius is 20 mm – this means that if I need to measure anything to the centre of the BB, I can simply measure to the outside edge of the shell and add 20 mm to get my final accurate measurement. For example, to get the BB height, I measured from the workbench surface to the bottom side of the BB shell, this came out at 250 mm so by adding the extra 20 mm, the BB height comes out at 270 mm – that is the first key identifying measurement I was looking for. Here are the rest of my initial measurements.

Everything matches so I’m happy that this frame is an SBDU Ilkeston Time Trial Special. The only thing that doesn’t match is the fork rake. SBDU time trial forks have a 37 mm rake, these have a standard road rake of 42 mm – I think that is always going to be a mystery!

So I’m happy and confident that this is a Time Trial Special, but ,my next mystery was the tubing. This is labelled as Reynolds 531c, but decals can be fitted at any time, so was this decal original. How do you find out, how can you tell what a piece of steel tubing is?

SBDU built primarily in 2 types of Reynolds tubing, starting in 1974 with 531 and then in 1975/76, they added 753 – that sounds simple, doesn’t it? It’s not! You have a choice of Metric or Imperial and you have single butted, double butted and plain gauge tubes. You then have different gauges of tubing and butting. SBDU also used different gauge tubes depending on frame size.

These are my questions on tubing…

– is it Reynolds 753?

– is it Reynolds 531?

– If it is Reynolds 531, is it 531SL (Special Lightweight)?

Reynolds 753 – Because my frame is so light, there is a possibility that it could be Reynolds 753 but with the incorrect 531c frame tubing decal fitted.. There is a tell-tale sign if you can spot it. 753 needed to be joined with Silver Solder (if you followed Reynolds recommendations – some manufacturers didn’t). 753 was heat treated tubing and had to be kept below 700 degrees during frame building otherwise the heat treatment and ultimate strength of the frame would be severely compromised. Silver Solder has a melting point normally below 650 degrees and uses a flux that becomes active at around 500 degrees. Reynolds 531 can withstand much higher temperatures and can be built with brass filler rod which has a melting point above 800 degrees. So how does this knowledge help to identify a frame material? Brass and Silver are different colours! If you have access to an unpainted part of the frame and can spot the filler rod colour in the joints of the tubes and lugs, you can sometimes see what was used and therefore the tubing. It isn’t scientific and isn’t guaranteed but is a general guide. My frame has good paint but the inside of the BB shell isn’t painted. Although SBDU were good builders and not much filler is seen outside of the joint, I can see brass in the BB shell – this frame can’t be 753; it has to be some kind of lightweight 531.

Reynolds 531SL (Special Lightweight) – 531SL later became known as Reynolds 531 Professional in the mid 80s, which then again turned into Reynolds 653 in the early 90s. This was very thin steel tubing but wasn’t heat treated like 753. That means it could be built (carefully) with brass. It was 531 that was drawn thinner during the manufacturing process. I am in an excellent position because I already own a 56 cm SBDU 531SL Time Trial Special frame with exactly the same size tubes, lugs and fittings; SB5464, built in the same year, 1982.

This identical frame built in 531SL is approx 50 grams lighter than my new frame so I think I can safely discount that my new frame is the same material. I’m confident now that SB5794 is not made from Reynolds 753 and it is not made from Reynolds 531SL. It must be made from 531c; just as the frame decal suggests.

One of the things I’ve collected over the years is old manufacturer material such as TI-Reynolds. Lots of information exists floating around the Internet, unfortunately, most of it is inaccurate and the more that people regurgitate this material, the more inaccurate it becomes. The only way to get accurate information is to get it directly from the source. I’ve got a small collection of Reynolds brochures that list details about its tubing. One such brochure lists the seat pin sizes for Reynolds seat tubes.

As you can see, for a seat tube with an outside diameter of 28.0 mm (Metric tubing like my frame), there are 5 different gauges, 4 different gauges for single butted tubes! I’ve measured the internal diameter of the seat tube/lug and it comes to 26.6. That, according to this document gives a wall thickness of either 0.7/0.55 or 0.8/0.55 (mm).

I think I’m at the end of my investigations for now. I started the process thinking I had an SBDU Time Trial Special frame made from Reynolds 531c but with no evidence to back that up. I’m now happy that I’ve checked all I can to confirm that this is correct. The only way I could be absolutely certain, would be to trash the frame, cut out the tubes and cut each tube in 2 and measure the wall thicknesses; obviously, that isn’t going to happen.

It’s going to build up into a nice, light bike that I’m going to enjoy. Eventually, I might get access to more information that can help to confirm things further; but for now, I need parts!